Japanese auto giant Toyota has developed a system to recycle “boil-off” gas for liquid hydrogen-fuelled vehicles.

While liquid H2 has a higher energy density by volume than compressed gas, which would reduce refuelling costs, the molecules must also be kept at temperatures below minus-253°C, or close to absolute zero.

However, there is an inherent problem with storing liquid hydrogen — ambient temperatures cause H2 at the edges of storage tanks to warm up, turning it into a gas (known as “boil-off”), which must be vented to prevent a build-up of pressure that could cause the tank to explode.

Currently, hydrogen boil-off is released straight into the atmosphere, which presents a problem both for project economics (since expensive volumes of H2 are lost) and environmental impact (since hydrogen acts as an indirect greenhouse gase).

As such, Toyota has developed a new system for liquid-hydrogen-fuelled vehicles that uses the boil-off gas to generate energy on the move, which it has trialled in its GR Corolla H2 Concept, a car which has a hydrogen-based internal combustion engine.

In this system, when boil-off gas builds up in the storage tank, it is vented into “a self-pressuriser”, which increases pressure by between two and four times without using external electricity. The pressurised gas is then directed into the engine to be burned as a fuel.

Surplus boil-off gas that is not re-pressurised is fed into a small fuel-cell stack to generate electricity, which can then be used to power the liquid hydrogen pump for the motor and increase overall energy efficiency.

Any remaining hydrogen molecules are run through a catalyst that produces water vapour, which is then vented. Although water vapour itself is a greenhouse gas, it has a short lifecycle in the atmosphere and has less of an impact on warming than CO2 or methane.

Toyota had demonstrated this system with a run of its GR Corolla H2 concept at the ENEOS Super Taikyu race final at Fuji Speedway. However, it is unclear how effective the system is over time, particularly since boil-off gas tends to build up when liquid hydrogen is left in the tank, rather than when the vehicle is in use.

A previous design of the car had been pulled from the Super Taikyu race in 2023 due to a vehicle fire associated with a hydrogen leak.

In a press statement, Toyota blamed the fire on a piping joint near the engine which had been loosened by vehicle vibration, causing a leak of hydrogen gas which then ignited.

Although the vehicle’s H2 leak sensor had worked to shut off further supply, the automaker was unable to “recover the vehicle in time”, suggesting that there had been some damage to the car.

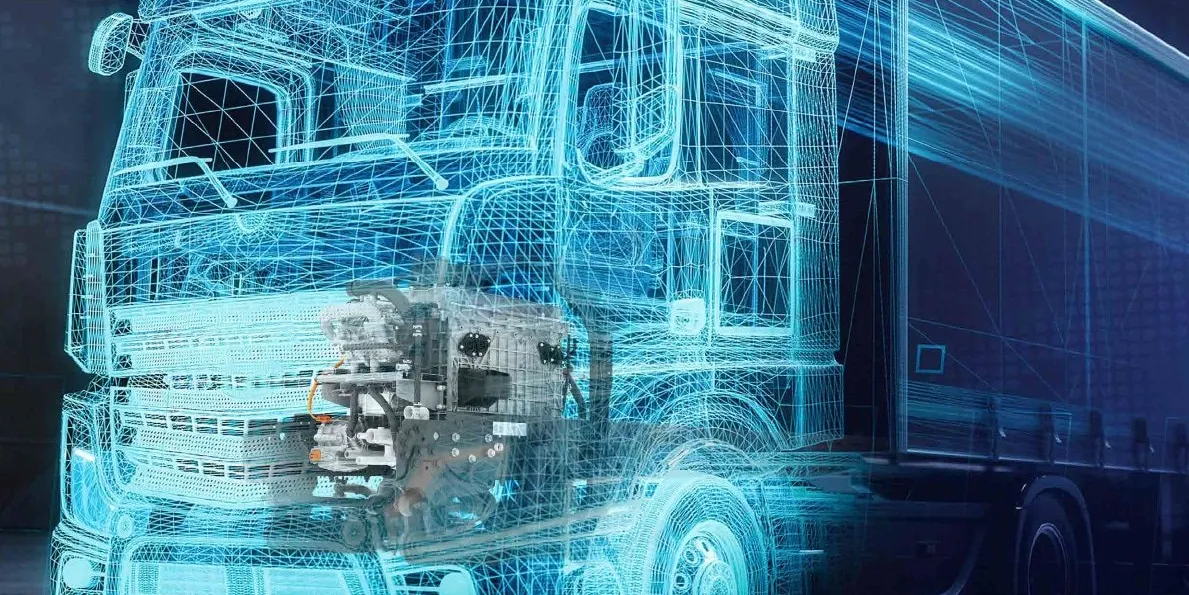

A number of other automakers are developing vehicles that can run on liquid hydrogen, such as Daimler and Hyzon, although both of these are focusing on heavy-duty trucks rather than cars.

Daimler was recently awarded €235m ($245m) of taxpayer money by German authorities to develop, produce and test 100 of its liquid-hydrogen heavy-duty trucks in real customer operation.